About CNC Turning

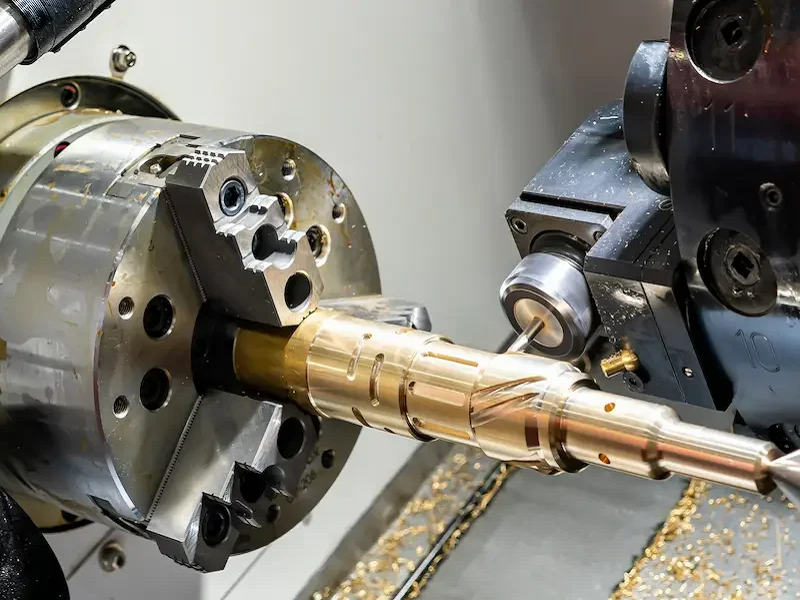

CNC turning removes material by mounting a blank on a rotating chuck and bringing the tool into contact with the workpiece, which is spinning at high speed. It is suitable for parts that are symmetrical about a central axis, such as round or tubular shapes. The CNC turning process is generally faster (and less expensive) than CNC milling, and meets the needs of parts with complex external geometries and internal holes, including various threading.

CNC Lathing

Besten precision CNC turning lathes provide high-quality custom prototypes and end-use production parts for simple and complex cylindrical geometries.we are always ready to provide you the on-demand CNC turning service and let you get reliable metal and plastic turned parts for your unique projects. our cnc turning lathes ensure to turned parts with high accuracy, regardless of the complexity. You will get durable parts from flats to radial and axial holes, slots, and grooves as fast as one day.

Materials for CNC Turning Parts

Based on your different projects requirements we can create precise rapid prototypes and low-volume production from various superior-quality materials. whether in metal or plastic ,our cnc turning services are compatible with a wider range of materials .

Aluminum

Titanium

Copper

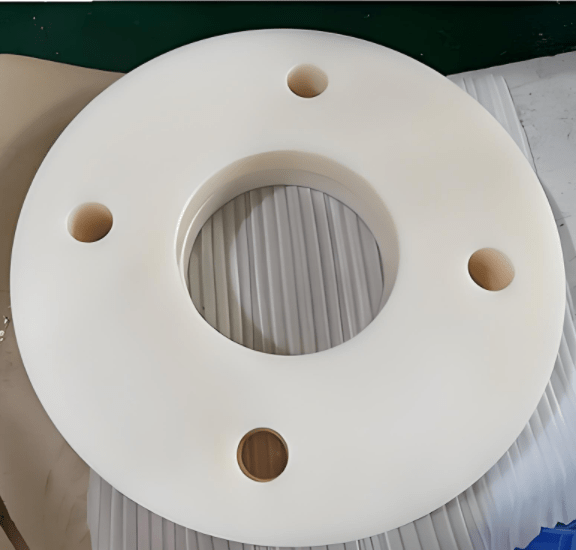

Plastics

Brass

zamak

Stainless Steel

Alloy steel

ECOSYSTEM

CNC Turning Surface Finishes

In order to improve the performance of parts, we can choose high-quality surface treatment to improve the hardness, roughness, chemical resistance and appearance of the product surface. Besten provides a variety of surface treatment methods for you to choose to meet your different needs.

| Item | Description | Materials | Color | Texture |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used are 2 types:type II anodizing(coating thickness: 12-18μm for black, 8-12μm for clear, and 4-8μm for color) and type III anodizing(hard anodizing, provides excellent corrosion and wear resistance). | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Powder Coating | Powder coating applied as a free-flowing, dry powder and works as a thin layer of protective polymer on the surface of the part.Unlike conventional liquid paint , powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | involves coating a metal part with a very thin layer of another metal or metal alloy, in order to protect from corrosion and oxidation of the base part or to change its cosmetic appearance. Tin, Nickel, Zinc (galvanizing), and Chrome are all common plating metals. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | satin |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | PC,PMMA,Aluminum, Brass, Stainless Steel, Steel | n/a | Glossy |

| Printing & Etching | You can choose silk screening,pad printing or laser etching for different structures ,silk screening can be used for larger surfaces and when mixing multiple colors for even more complex graphics; pad printing can be used for printing on curved surfaces; laser etching is ideal for making precise and permanent marks on metal and some plastics. | Aluminum, Brass, Stainless Steel, Steel | n/a | n/a |

CNC turning design reference

Based on our more than 10 years experience of cnc turning, we would like to give us recommended and technically feasible values for the commone structures of prototypes processed through precision cnc turning.

| Structure | Recommended size | Feasible size |

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter: standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |

More resources for CNC turning

- 1. What is your maximum diameter capacity for turned parts?

For turning parts the diameters ranging from 0.5mm to 65mm for stock bars. Our turning capabilities can reach up to 3000 mm for billets.

- 2. Can you produce plastic turned parts?

Yes, our CNC turning services include plastic parts manufacturing and metal prototype manufacturing. We can produce small or large batch prototypes and production parts from various engineering-grade plastics.

- 3. What’s the difference between CNC milling and CNC lathe?

For CNC milling and CNC lathe the major difference are their machining process.CNC milling is rotating the cutting tools against a stationary bar stock or workpiece and more suitable for machining irregular and flat structures. but in contrast CNC lather works by rotating the bar stock or workpiece against a stationary tool and work best for cylindrical or conical parts.

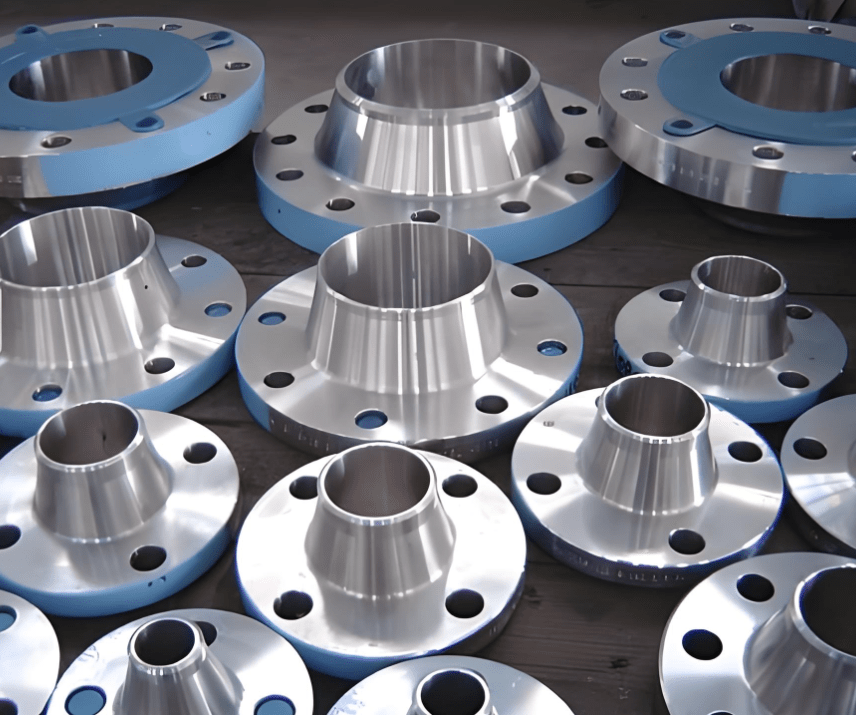

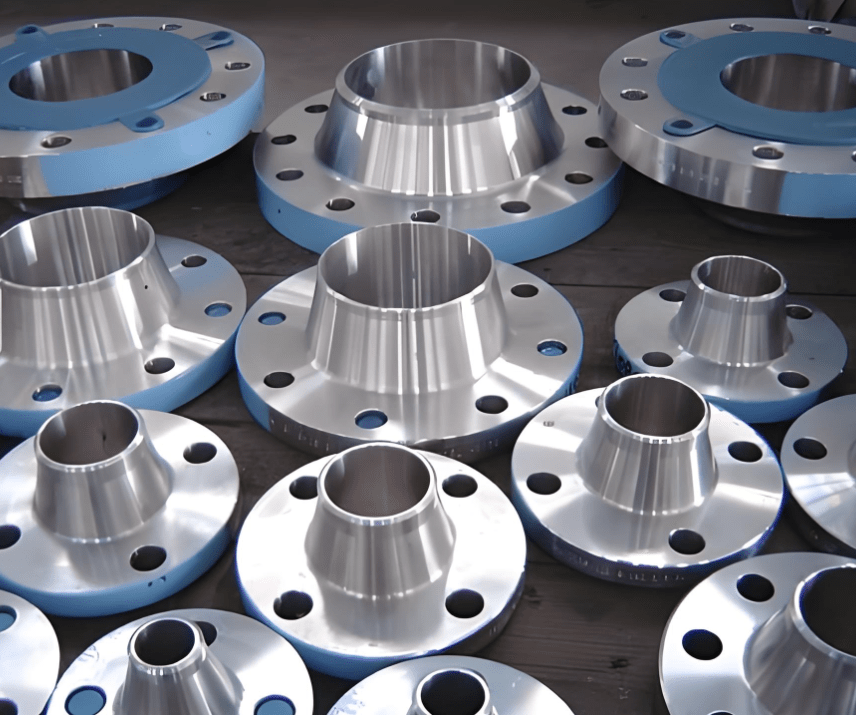

CNC Tuning Gallary

- 3. What’s the difference between CNC milling and CNC lathe?

For CNC milling and CNC lathe the major difference are their machining process.CNC milling is rotating the cutting tools against a stationary bar stock or workpiece and more suitable for machining irregular and flat structures. but in contrast CNC lather works by rotating the bar stock or workpiece against a stationary tool and work best for cylindrical or conical parts.

From Besten Blogs

CNC Plastic Machining: What Is It, Creating Prototypes, Operations, Materials

Gallery of CNC Turning Parts

Quote Now to Start Your CNC turning Project

From prototype to production ensure high quality, fast delivery and competitive prices with our one-stop cnc turning services.