Unlocking the Potential of CNC Plastic Machining for Prototyping

In today’s fast-paced manufacturing world, efficiency and precision are critical. One of the most effective methods to achieve both in prototype development is CNC plastic machining. This technology not only enhances the speed of prototype production but also ensures high-quality results. Here’s why CNC plastic machining is the ideal choice for your prototyping needs.

What is CNC Plastic Machining?

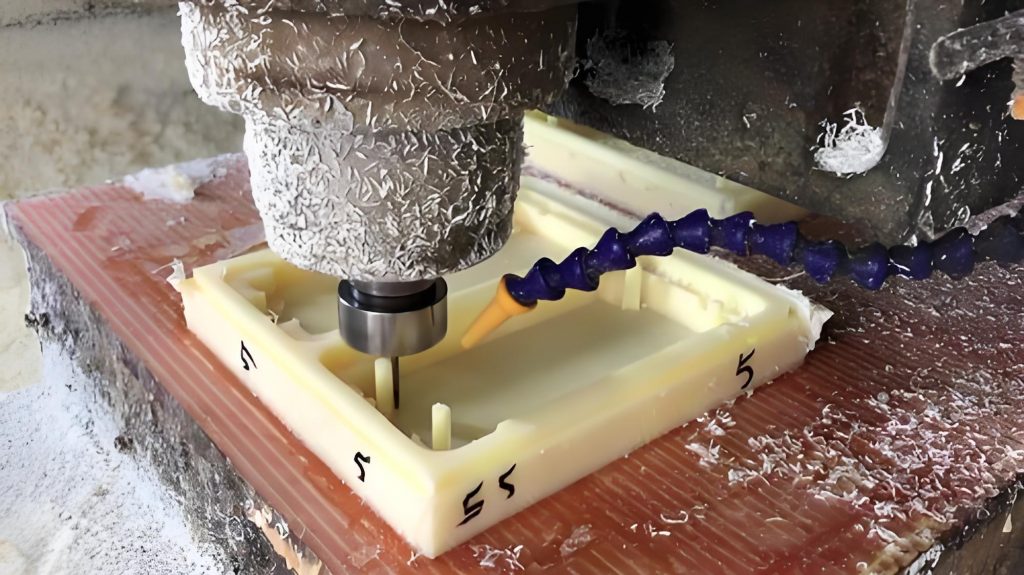

CNC plastic machining involves the use of computer numerical control (CNC) machines to create intricate plastic parts with high precision. This technique is widely used in various industries to produce prototypes that closely mimic the final product’s specifications. The process allows for rapid production and modification, making it a go-to solution for designers and engineers seeking efficiency and accuracy.

Benefits of CNC Plastic Machining for Prototypes

- Precision and Accuracy: CNC machines operate with exacting standards, producing prototypes that match the digital designs with remarkable accuracy. This precision is crucial for testing and validating designs before moving to full-scale production.

- Versatility: CNC plastic machining supports a wide range of plastic materials, including ABS, polycarbonate, and nylon. This versatility ensures that prototypes can be made from the most suitable material for their intended application.

- Speed: The CNC machining process is faster compared to traditional methods. This quick turnaround is essential for meeting tight deadlines and accelerating product development cycles.

- Cost-Effective: While initial setup costs for CNC machining may be higher, the long-term benefits include reduced material waste and the ability to make adjustments without needing new molds. This cost efficiency is particularly advantageous for producing multiple prototypes.

- Complex Geometries: CNC machines can handle complex geometries and intricate details that are often challenging for manual machining processes. This capability allows for the development of prototypes with advanced features and designs.

Applications of CNC Plastic Machining in Prototyping

CNC plastic machining is applicable across various industries:

- Automotive: For creating parts that require high durability and precise fit.

- Aerospace: To develop lightweight components that meet rigorous standards.

- Medical Devices: For producing prototypes that require compliance with stringent regulatory standards.

- Consumer Electronics: To create components that are both functional and aesthetically pleasing.

How to Get Started with CNC Plastic Machining

To leverage the benefits of CNC plastic machining, follow these steps:

- Define Your Prototype Requirements: Determine the material, dimensions, and features needed for your prototype.

- Choose a Reputable CNC Machining Service: Look for a provider with experience in CNC plastic machining and a track record of high-quality prototypes.

- Submit Your Design: Provide detailed CAD files to ensure that your prototype is manufactured according to your specifications.

- Review and Refine: Work with your CNC machining partner to review the prototype, make necessary adjustments, and finalize the design.

Conclusion

CNC plastic machining is a powerful tool for prototyping, offering precision, speed, and versatility that traditional methods cannot match. By utilizing this technology, you can streamline your development process, reduce costs, and bring innovative products to market faster. Embrace CNC plastic machining for your next prototype and experience the advantages firsthand.

For more information on how CNC plastic machining can benefit your prototyping projects, contact us today. Let us help you turn your ideas into reality with unparalleled precision and efficiency.

Leave a Reply