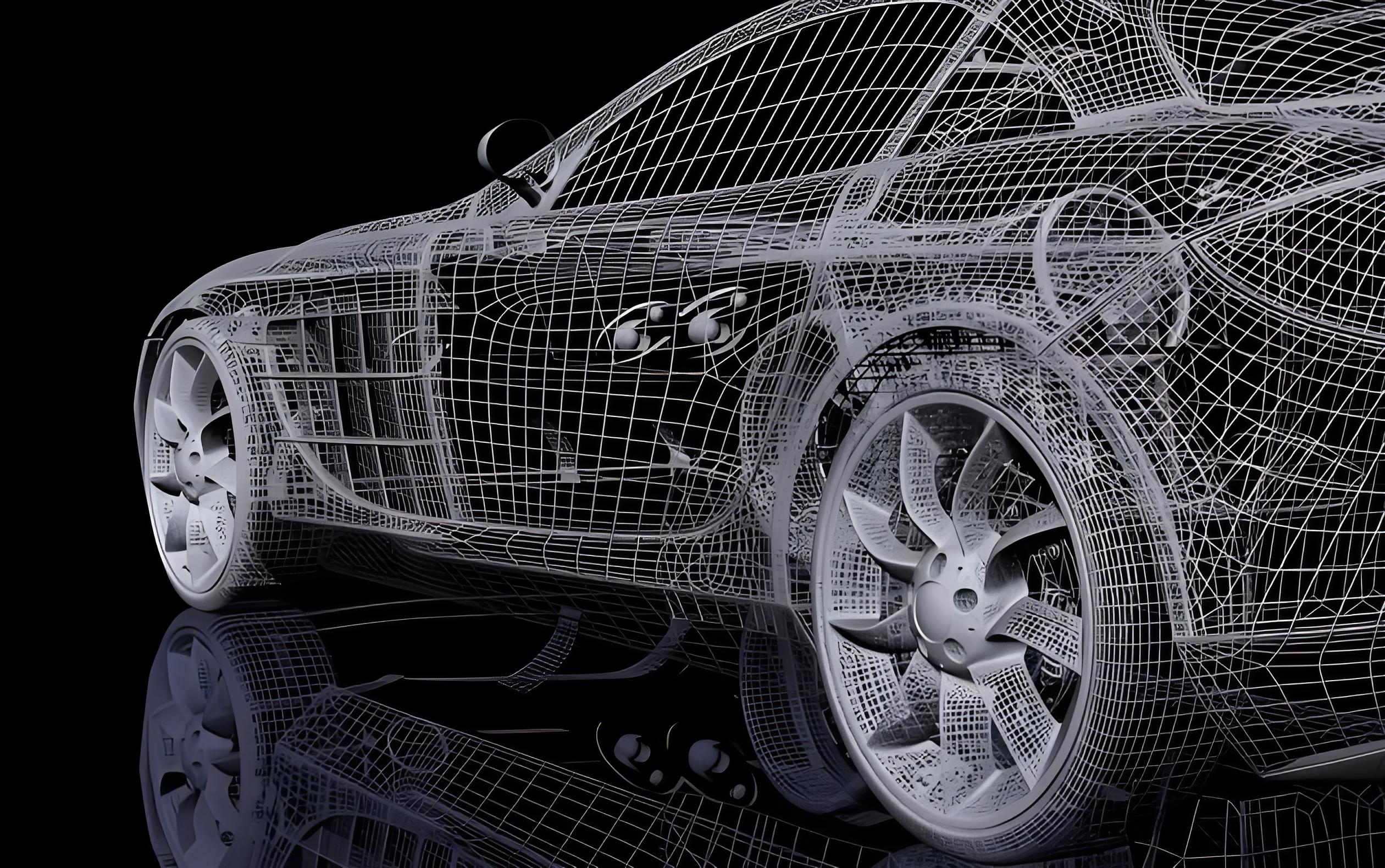

Advanced Automotive Prototyping and Precision Parts Manufacturing

Bespoke automotive prototyping and parts manufacturing services for vehicle product development. Enjoy streamlined production processes, competitive pricing, and flexible on-demand manufacturing

Certified for automotive manufacturing

Comprehensive quality documentation

Highest quality standards

Automotive Production Expertise

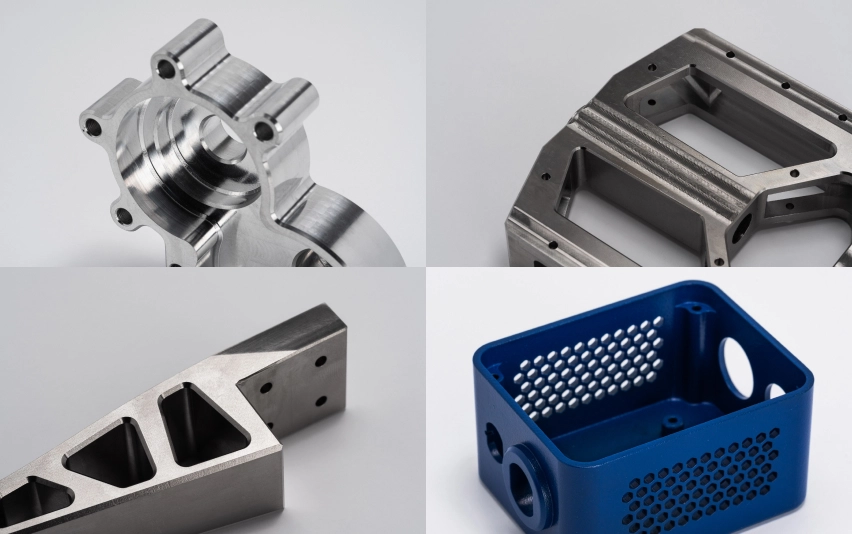

Our advanced multi-axis CNC machines enable us to achieve high precision in manufacturing. In addition to CNC machining, we utilize additive manufacturing, vacuum casting, sheet metal fabrication, and rapid tooling to remain competitive in the auto parts industry. We offer an extensive range of post-processing techniques, including heat treatment, plating, coating, and anodizing. Each process undergoes rigorous upfront review, continuous monitoring, final inspection, and post-review to ensure quality.

By implementing stringent process control techniques and paying meticulous attention to detail, we deliver top-tier quality and precision. Our primary goal is to ensure our clients receive exceptional service. We also offer coordinate measuring machine (CMM) services and third-party inspection and certification upon request to meet the needs of our valued customers.

Expertise in Automotive Prototyping and Parts Manufacturing. Discover the optimal process for your needs with Besten and enhance your product experience. We are committed to delivering solutions tailored to meet your specifications.

GET A INSTAND QUOTE

The Importance of Prototyping in the Automotive Design and Development Process

- Validation of Design Concepts: Prototyping enables the evaluation of design concepts in a tangible form, allowing for visual and functional validation before committing to mass production.

- Identification of Design Flaws: By creating prototypes, potential design flaws and issues can be identified and addressed early in the development cycle, reducing the likelihood of costly modifications during later stages.

- Testing and Optimization: Prototypes provide the opportunity to conduct various tests, including structural integrity, aerodynamics, and performance testing, which are crucial for refining and optimizing the design.

- Client and Stakeholder Communication: Physical prototypes facilitate effective communication with clients, stakeholders, and team members, enabling them to visualize the end product and provide valuable feedback for refinement.

- Cost Reduction: Addressing design flaws and optimizing performance during the prototyping phase can lead to cost savings by avoiding expensive rework and modifications in the later stages of production.

- Accelerated Innovation: Rapid prototyping techniques enable faster iteration and innovation, allowing automotive companies to stay competitive by bringing new and improved designs to market more efficiently.

Automotive manufacturing capabilities

Besten’s Automotive Prototyping and Parts Manufacturing Technology: Essential at Every Stage of Development.

Mastering Diverse Manufacturing Techniques for Swift Design Realization. Collaborating with You Across Every Phase of Automotive Design and Development.

CNC Machining

CNC Milling,CNC Turning ,Metal and Plastic prototyping

3D Printing

3D printing service,SLA,SLS,FDM

Vacuum Casting

Mold making ,soft rubber and solid parts,clear or unclear casting

Sheet Metal Fabrication

Sheet metal cutting and bending service,Laser cutting

Clear Prototyping

Car lighting transparent prototyping,PC and PMMA clear polishing

Post Finishing

As machined,smooth machining,aluminum anodizing,blasting,powder coating etc

Materials & surface finishes for automotive parts

Through our professional post-processing technology team and professional material suppliers around the world, you can get a wide range of materials and surface treatment products suitable for various applications.

Automotive materials

Automotive surface finishes

Select from a broad range of industrial-grade materials

Steel, mild steel & stainless steel: 304/304L, 316/316L, 430, 301, 4140, 4340, Tool Steels

Titanium: 1, 2, 5

Aluminum: 6061-T6, 6063, 5052, 5083-H111, 2017, 7075-T651

Thermoplastics: Polyethylene (PE), Polypropylene(PP), Polycarbonate (PC), ABS

Commodity polymers: Polyethylene terephthalate (PET), Polyvinyl chloride (PVC)

How Besten helps automotive companies innovate

Complex Geometries Utilizing State-of-the-Art Processes

We can achieve incredible geometric complexity. No matter how complex your design, we can produce anything you give us with excellent mechanical and cosmetic performance. Our latest 3D printing and CNC technology, including 5-axis machines, makes it easy to produce rapid prototypes and low-volume production parts.

Accelerate Your Project Timeline with Rapid Quotes and Expert Design Support

In the fast-paced automotive industry, timely innovation is crucial. Skip the long wait times for quotes; we provide responses within 24 hours. Quickly compare quotes and expedite parts production to stay ahead in the automotive revolution. Whether you need tooling equipment for testing, a single part for fleet deployment, or a technology upgrade for automotive electrification, Besten offers the comprehensive solutions you need.

Automotive Lighting Lamps: Advanced Prototypes for Optical Components

In the fast-evolving automotive industry, lighting systems play a crucial role in both functionality and aesthetics. The development of optical component prototypes for automotive lighting lamps is a key phase in ensuring that these systems meet high standards of performance, safety, and design.

Precision Engineering in Optical Prototyping

Optical component prototypes are meticulously crafted to evaluate and refine the performance of automotive lighting systems. This stage involves precision engineering to achieve the desired optical properties, such as light distribution, intensity, and clarity. Advanced techniques like 5-axis CNC milling and diamond turning are employed to create prototypes with complex geometries and fine details.

Vacuum Casting in automotive industry

In the realm of custom auto parts, low-volume manufacturing plays a pivotal role in meeting niche market demands and delivering specialized solutions tailored to specific automotive needs. This approach offers distinct advantages in flexibility, customization, and rapid prototyping, catering to enthusiasts, collectors, and innovators alike.

Flexibility in Design and Production

Low-volume manufacturing enables automotive enthusiasts and designers to explore unique designs and configurations that may not be feasible in mass production. Whether it’s bespoke components for vintage car restoration or performance upgrades for modern vehicles, this approach allows for creative freedom without the constraints of large-scale production requirements.

From Our Blogs

SLA 3D Printing: The Future of Rapid Prototyping?

SLA 3D Printing: The Future of Rapid Prototyping? SLA 3D printing, or stereolithography, is quickly becoming…

Types of Metals for CNC Metal Machining

Types of Metals Besten Offer for CNC Metal Machining When it comes to CNC machining,…

Unlocking the Potential of CNC Plastic Machining for Prototyping

Unlocking the Potential of CNC Plastic Machining for Prototyping In today’s fast-paced manufacturing world, efficiency…

3D Printing For Medical Industry

3D Printing For Medical Industry 3D printing has revolutionized the medical industry. It has enabled medical…

CNC Plastic Machining: What Is It,Creating Prototypes, Operations, Materials

CNC Plastic Machining: What Is It, Creating Prototypes, Operations, Materials CNC plastic machining is a…

How Besten Prototype suggest to reduce the cost of CNC machined parts through structural design

CNC machining parts are parts processed by CNC equipment. CNC machining usually refers to a…