Precision Parts

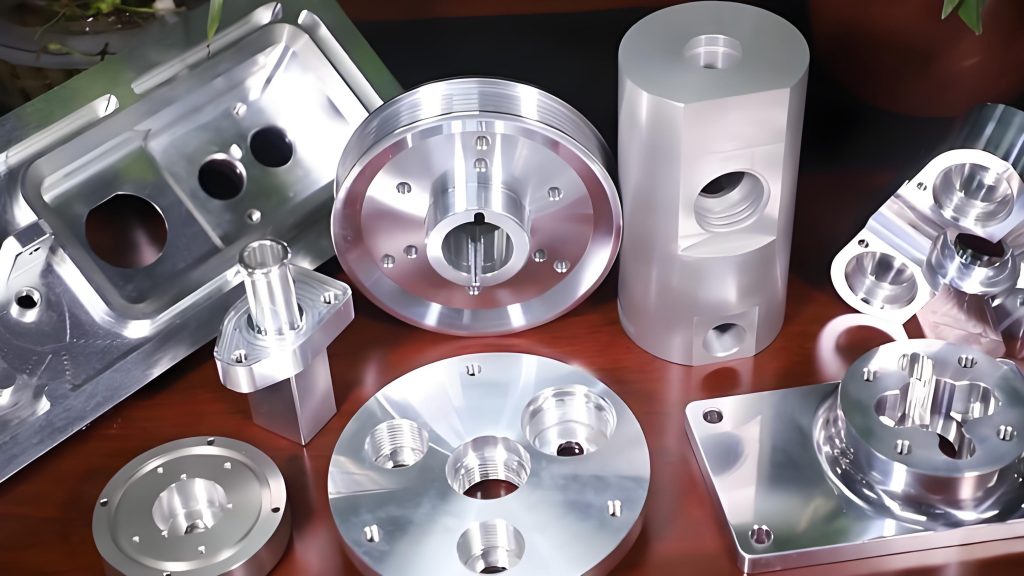

Our airplane device prototyping services ensure parts meet stringent tolerance and precision standards, capable of achieving tolerances as tight as +/-0.001 inches. Utilizing advanced machining technologies and our extensive expertise, we guarantee the accuracy and reliability of your airplane device prototypes.

Follow Us To Start Your Prototyping & Manufacturing Process

In recent years, Besten Prototyping has evolved into a leading manufacturer renowned for handling high-complexity and high-precision projects, along with offering an array of post-processing services. Our expertise and advanced capabilities in aerospace CNC machining have earned the trust of numerous aerospace clients, allowing us to meet the stringent requirements of space flight applications, including precise material specifications and tight tolerances. Additionally, through our network of reliable partners, we can streamline our customers’ supply chains by providing special processing services such as heat treating, plating, coating, anodizing, and various other surface treatments.

Prototyping

Obtain top-notch prototypes for early-stage product development to evaluate your designs, make crucial material and design adjustments, and prepare prototypes for testing. During this phase, we assist you in creating prototypes that align with your product’s specifications and design files. Based on your requirements, we employ cost-effective materials and processes to produce parts that closely resemble the final product.

Prototype Development

Following a thorough analysis of your design file, our skilled technicians will craft prototypes tailored to your precise design specifications. The choice of materials and processes used in the development of your component will be dictated by your specific application, ensuring that the prototype closely resembles the final product. This approach allows for comprehensive assessment of specifications and facilitates functional testing.

Engineering Verification and Testing

Effortlessly modify functional device prototypes following thorough engineering testing and validation of performance criteria.Rapidly and effortlessly iterate on accurate functional prototypes to ensure all performance criteria are fulfilled. Our functional prototypes enable you to detect and address any design risks efficiently. This process may involve multiple iterations to guarantee that the prototypes adhere to all functional requirements and performance standards.

We develop functional prototypes that closely mimic the final product, allowing for easy identification and resolution of design issues. Multiple iterations may be necessary to ensure all performance requirements are achieved.

Validation and Testing of Design

Efficiently Validate Performance, Functionality, and Aesthetic of Your Medical Product. Implement Necessary Design Iterations for Time and Cost Savings.

We provide advanced design solutions that include manufacturing feedback, enabling thorough analysis of both performance and aesthetics for your medical prototypes. Utilizing a variety of materials, finishes, and mechanical designs, we craft components optimized for ideal functionality and market testing readiness.

- Medical delivery systems

- Medical testing devices

- UV sanitation components

- Surgical instruments

- Implantable prototypes

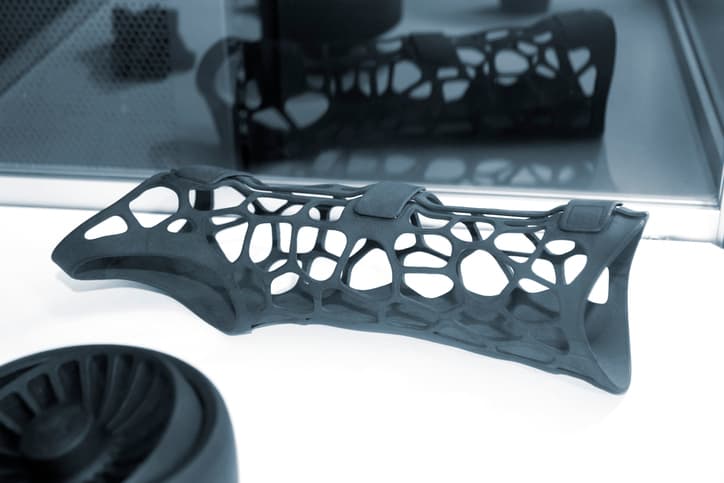

- Prosthetic components

- Microfluidics

- Ventilators

- Handheld devices

Large-scale Manufacturing

Mass production of medical devices involves the large-scale manufacturing of healthcare products to meet high demand and ensure consistent quality. This process requires strict adherence to regulatory standards, precise quality control measures, and advanced manufacturing technologies.

Transition from product testing phases to full-scale production of end-use medical components. Embrace stringent quality standards and superior manufacturing capabilities to ensure high-quality outcomes. Our advanced manufacturing techniques and engineering expertise elevate your medical device production to the next level.

Foucs On Our Manufacturing Services

Our meticulous attention to detail ensures precise and high-quality machining at every stage. With well-trained staff and rigorous deburring, cleaning, assembly, and packaging processes, we guarantee that your order not only meets but exceeds your exacting standards.

CNC Machining

CNC Milling,CNC Turning ,Metal and Plastic prototyping

3D Printing

3D printing service,SLA,SLS,FDM

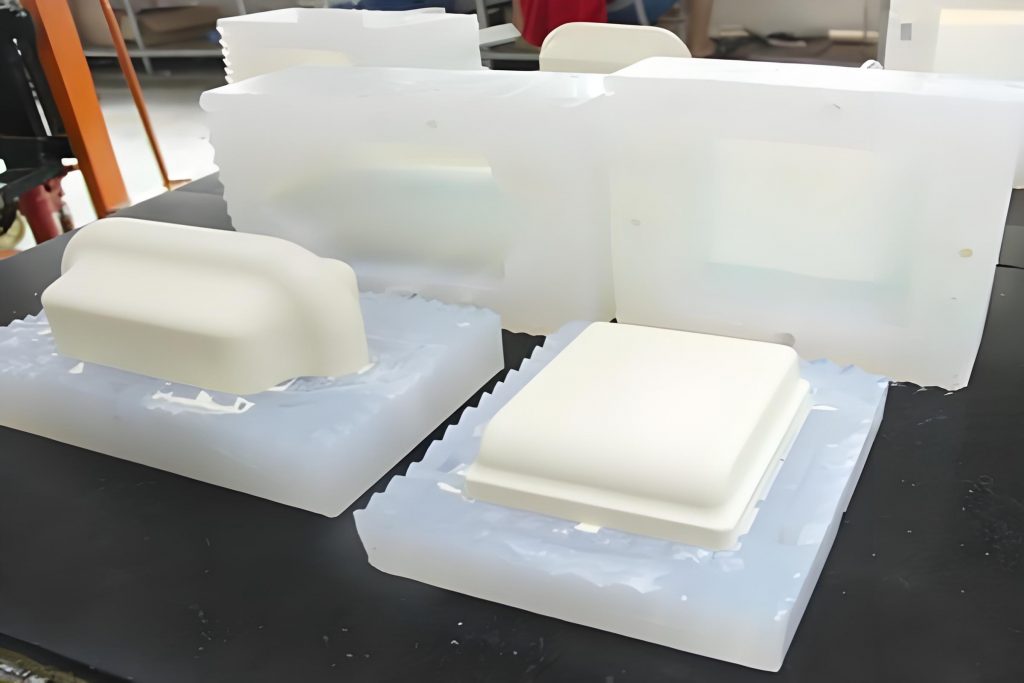

Vacuum Casting

Mold making ,soft rubber and solid parts,clear or unclear casting

Sheet Metal Fabrication

Sheet metal cutting and bending service,Laser cutting

Clear Prototyping

Car lighting transparent prototyping,PC and PMMA clear polishing

Post Finishing

As machined,smooth machining,aluminum anodizing,blasting,powder coating etc

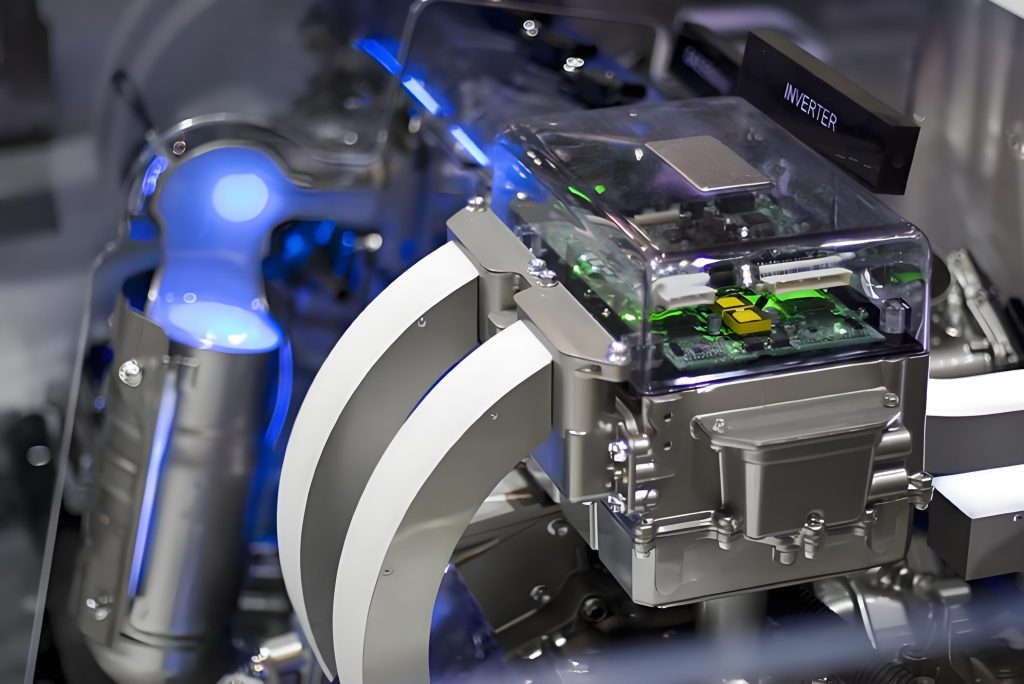

Applications of Aerospace Components

With our advanced manufacturing capabilities, we are able to expedite the production of a vast array of aerospace components, catering to an extensive range of unique and specialized applications. Our expertise enables us to meet the stringent requirements of the aerospace industry, ensuring the highest level of precision, quality, and performance. Here are some of the commonly encountered aerospace applications where our components find their purpose:

Materials &

Surface Finishes

CNC Materials

Select from more than 30 metal alloys and hundreds of industrial-grade plastics.

Surface Finish

Improve durability and performance with a selection of finishes

Blog &News

We continuously share our expertise in cutting-edge manufacturing through our informative articles. Dive into stories about advanced rapid prototyping and rapid manufacturing technologies to help you optimize your product design and discover superior solutions for new product development.

Contact Us Right Now