What is CNC Milling

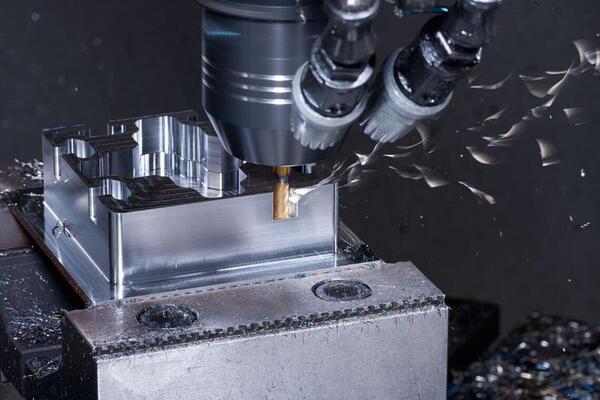

CNC milling uses rotational cutting tools to remove material from a workpiece based on the programming steps to produce prototypes. This cnc milling manufacturing process works well for many materials, including metals, polymers, wood and plastics. Gernerally CNC milling systems has 3 linear degrees of freedom: the X, Y and Z axis. This allows for top-notch precision and detailing. at Besten we also offers more advanced, 5-axis systems, where the tool head and machining bed (A and B axis) can also rotate. 5-axis CNC machines can produce parts with high geometric complexity without needing multiple machine setups also with high precision.

3 Axis CNC Milling

CNC 3-axis milling is a subtractive manufacturing method and the most widely used rapid model processing method. It can process various plastic and metal materials. It mainly uses the movement and rotation of the cutting tool to remove materials to complete the final structural model. This processing method is suitable for parts with low precision requirements and not very complex structures.

Precision CNC Milling

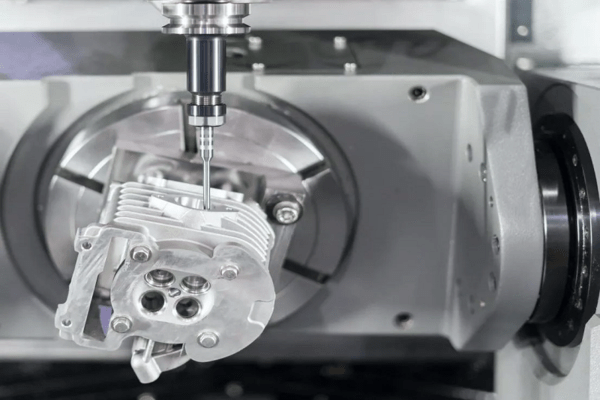

With our years of experience and advanced technology, we can provide high-precision machining. If you need to achieve strict accuracy requirements of ±0.0005 inches or better, Besten will be your best choice. We have advanced testing equipment, and we can meet your high-precision CNC machining needs even for the most complex parts.welcome to contact us and let us to creat you a high precision project.

5 Axis CNC Milling

5-axis CNC machining allows complex structural parts to be machined on multiple sides in one programming. This can bring huge benefits, reduce machining time and improve machine utilization. At the same time, five-axis machining is more cost-effective and can shorten the project machining cycle as quickly as possible.

GET IN TOUCH

Get A Instant Quote

CNC Milling Tolerances

At Besten, our standard tolerances for CNC milling metals are ISO 2768-m, and our standard tolerances for plastics are ISO 2768-c. Typically, we can maintain CNC machining tolerances between ±0.005″ (±0.125mm) and ±0.002″ (±0.05mm). We are committed to precise measurements to provide our customers with consistent, high-quality results, and Besten ensures accuracy through our CNC milling tolerance standards.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

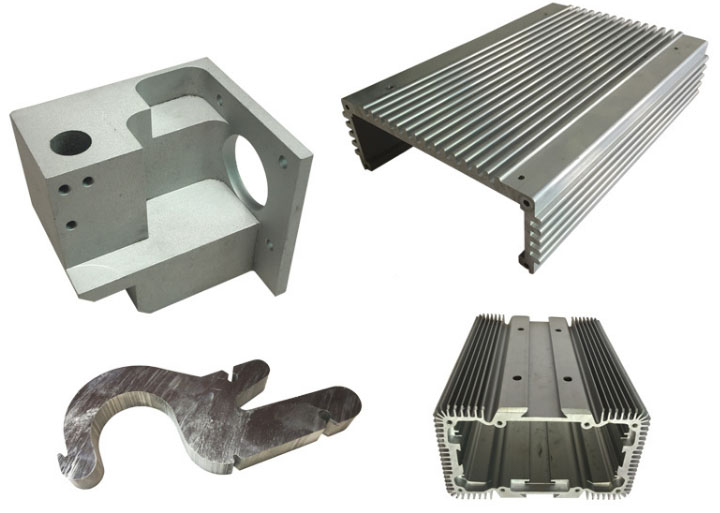

Materials for CNC Milling Parts

Metal Materials

Metal CNC machining can using a wide range of materials and widly be made prototype concept models ,visual presentation prototypes ,function and working prototoypes and design engineering verification etc.

Aluminum,Stainless steel ,Brass,Zamak 3 /zamak 5/Zinc,Titanium,Bronze ,Steel,Copper

Plastic Materials

At Besten we can providing CNC plastic prototype manufacturing service from different material for you to test your concept models ,visual presentation prototypes or verify your design engineer works .we are allow almost all the plastic materials such as :ABS PMMA POM PC PA PP PBT PPS PE etc.

CNC Milling Surface Finishes

In order to improve the performance of parts, we can choose high-quality surface treatment to improve the hardness, roughness, chemical resistance and appearance of the product surface. Besten provides a variety of surface treatment methods for you to choose to meet your different needs.

| Item | Description | Materials | Color | Texture |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used are 2 types:type II anodizing(coating thickness: 12-18μm for black, 8-12μm for clear, and 4-8μm for color) and type III anodizing(hard anodizing, provides excellent corrosion and wear resistance). | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Powder Coating | Powder coating applied as a free-flowing, dry powder and works as a thin layer of protective polymer on the surface of the part.Unlike conventional liquid paint , powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | involves coating a metal part with a very thin layer of another metal or metal alloy, in order to protect from corrosion and oxidation of the base part or to change its cosmetic appearance. Tin, Nickel, Zinc (galvanizing), and Chrome are all common plating metals. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | satin |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | PC,PMMA,Aluminum, Brass, Stainless Steel, Steel | n/a | Glossy |

| Printing & Etching | You can choose silk screening,pad printing or laser etching for different structures ,silk screening can be used for larger surfaces and when mixing multiple colors for even more complex graphics; pad printing can be used for printing on curved surfaces; laser etching is ideal for making precise and permanent marks on metal and some plastics. | Aluminum, Brass, Stainless Steel, Steel | n/a | n/a |

Reply within 12 hours

Quick Response

ISO Standard

Excellent Quality

20% Lower Price

Cost-effective Solution

All the world

Countries Served

From Besten Blogs

How Besten prototype suggest to reduce the cost of cnc machined parts through structural design

CNC machining parts are parts processed by CNC equipment. CNC machining usually refers to a precision machining method controlled digitally by a computer. It has now become a common machining method.

CNC Plastic Machining for Acrylic CNC Machining

Acrylic CNC machining is a manufacturing process that uses computer-controlled machines to shape acrylic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape acrylic materials into precise shapes and sizes.

CNC Plastic Machining: What Is It, Creating Prototypes, Operations, Materials

CNC plastic machining is a manufacturing process that uses computer-controlled machines to shape plastic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape plastic materials into precise shapes and sizes.